The Basic Principles Of Mfg s

Wiki Article

Die Casting for Dummies

Table of ContentsFacts About Lean Manufacturing RevealedSome Of OemSome Of Plastic ManufacturingExcitement About Hon Hai PrecisionWhat Does Manufacturing Industries Mean?See This Report on Additive ManufacturingManufacturing Industries - Truths

It's additionally possible to make use of insert molding to add plastic components over existing parts constructed out of various other materials. The basic concepts behind the injection molding process might appear easy, but in truth, it is a very challenging procedure that requires the ideal devices and also the right proficiency. Nevertheless, when it is implemented correctly, shot molding can consistently create exceptional outcomes also for the most tough production jobs.

Equally as with any kind of production approach, there are benefits as well as negative aspects that can relate to different scenarios, and also just by understanding them can you make an educated choice. Keeping that in mind, let's discuss a few of one of the most substantial advantages and disadvantages that injection molding can offer. Pros, Initially, allow's discuss the pros of selecting to manufacture with a shot molding maker.

Manufacturing - Questions

That suggests that with every run, you can produce a part that is the same to the one preceding it, over and over again. As you can visualize, this sort of accuracy is vital in nearly all markets, and also especially in those that can't endanger on top quality, which is why shot molding is popular in highly-demanding fields like aerospace as well as automobile.That suggests that you can not just reduce the chances of human error to a minimum, but additionally have the machine produce parts at a constant rate as well as a high fulfillment price. Price Efficiency, Essentially, injection molding is among the most economical services for creating components that you can discover.

Large Range of Products, If there's one point that injection molding truly stands out at, it's the ability to customize the materials as well as surfaces according to nearly any type of kind of demands. You can choose plastic, polycarbonate rubber, chemical immune plastics, eco-friendly, and also lots of others, so just be sure to determine what you need from the component and also you'll have lots of choices.

The 2-Minute Rule for Oem

Eco-Friendly, Lastly, in a globe where being conscious of the environment is extra essential than ever before, injection molding can be helpful due to the fact that it produces nearly no waste. All material that isn't made use of in the mold and mildew can be repurposed and utilized in future tasks. Cons, Since we have actually looked at why injection molding is so efficient, allow's consider several of its imperfections to supply you an extra well-rounded photo.However, before you can really make, you will certainly require to develop as well as produce the mold and mildew itself, which can take check out here many hours and also a great deal of manpower to carry out appropriately. Still, although this procedure can be intricate, once it's done, you can use the mold and mildew to create countless parts rapidly.

Getting The Mfg To Work

Applications of Shot Molding, When producing parts, precision and cost-effectiveness are 2 of one of the most important considerations that the majority of companies are trying to find. That's why it's not surprising that a process such as injection molding has become so popular as well as has been utilized both for smaller runs, in addition to massive manufacturing of parts with tight tolerances.Food & Beverage, As we discussed earlier, injection molding provides companies the capability to create components from a variety of products. And also that's really vital in a sector such as food & drink due to the fact that it needs to abide by a large variety of regulations regarding the safety of food containers.

This, incorporated with the reasonably inexpensive of manufacturing, makes injection molding perfect for creating components such as food containers, drink caps, filtering elements, and far more. Building and construction Components, One more market that makes use of shot molding innovation is developing and building and construction, where the personalized as well as complicated plastic components play an essential function in the process of constructing homes and frameworks (manufacturing industries).

The smart Trick of Die Casting That Nobody is Discussing

A number of the important clinical devices such as heart pumps, numerous screens, in addition to a variety of clinical tools all depend upon the precision of shot molding, which makes the technology irreplaceable in the area. Just How to Pick Injection Molding Solutions, Even though injection molding can be incredibly helpful in a variety of industries, in order for any one of that to matter, you should select a trusted and knowledgeable companies that can take your vision and turn investigate this site it into truth.

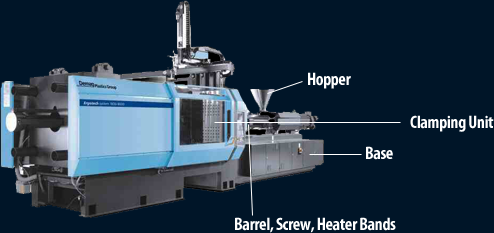

As you now recognize, the process of making and developing the mold can be challenging, so you need skilled professionals that can aid you get over any type of difficulties that you run into. Along with seasoned team, the service provider visit this site ought to also have the most sophisticated shot molding equipment modern technology since that plays a crucial role in exactly how exact the parts can be, exactly how rapidly they can be produced, and also the length of time will certainly it take to start the manufacturing procedure.

Unknown Facts About Additive Manufacturing

When you require to scale up production, you do not desire to need to look for a new supplier simply since the firm became unable of doing bigger runs.Photo: Components prior to sintering (back) as well as after sintering (front). (Photo politeness of PCC Advanced) Blade clamp for a power tool: Changing a multiple-component setting up with a steel shot built part. (Image politeness of Kinetics Inc.) To make a complex component in steel, you can cast it, or equipment it or shot mold it.

Shot molding by blending metal powder with plastic, molding it and afterwards removing the plastic as well as sintering the component. The process is called metal shot molding (MIM), or occasionally powder injection molding (PIM), and also it can generate complex components in a large range of steels, including steel, stainless-steel, and also even high-temperature alloys. manufacturing industries.

The Only Guide to Additive Manufacturing

Industries that now use MIM components include aerospace, clinical, electronic devices, weapons and also customer items. You might be familiar with powdered steel, or PM, parts, especially as bearings, bushings as well as small equipments. PM parts are created of steel powder compressed in a die and after that sintered. There are numerous related processes that additionally utilize steel fragments.Report this wiki page